Overview of Electrical Components

Electrical components serve as the backbone of myriad industrial applications, driving both operational efficacy and technological advancement. Central to optimizing industrial outcomes, these components range from the ubiquitous to the highly specialized. Key among them are resistors, capacitors, and inductors, which play integral roles in regulating the flow of electric current, storing energy, and maintaining circuit stability. Their precision engineering ensures reliability in critical processes.

Transformers and diodes further exemplify the sophisticated interplay of electricity and machinery. Transformers are pivotal in voltage regulation, enabling the seamless adjustment of electrical energy to suit diverse operational demands. Diodes, on the other hand, serve as gatekeepers, directing current flow with precision to protect and enhance circuit functionality.

The inclusion of semiconductors heralds a leap into advanced control and signal processing. As the nerve centers of modern electronics, these devices underpin the creation of intricate control systems and are indispensable in achieving high-efficiency rates in energy consumption.

Furthermore, switches and relays are employed as tactile interfaces, providing vital control over complex electrical systems. Their capability to trigger or halt electrical flow is essential for safety and functionality.

As industries incessantly evolve, the role of these components expands, reinforcing the imperative for continual innovation and adaptation. This dance of electrons, orchestrated by human ingenuity, continues to be the cornerstone of industrial progression, propelling industries toward unparalleled efficiency and sustainability.

For additional insights on associated topics, explore the intricacies of Plastic Systems cables in modern industries and understand how industrial plugs and sockets enhance operational efficiency.

Significance of High-Performance Solutions

High-performance solutions (HPP) have become pivotal in enhancing the efficiency and reliability of industrial applications, seamlessly integrating into complex systems to deliver optimal functionality. These solutions are characterized by an amalgamation of advanced engineering and innovative design, tailored to meet the stringent demands of modern industrial environments. HPP solutions are indispensable, addressing the intricate requirements for speed, durability, and precision that regular systems often fall short of meeting.

In the realm of industrial applications, the significance of high-performance solutions is underscored by their ability to withstand rigorous conditions while maintaining consistent performance levels. This is particularly critical in sectors where the margin for error is negligible, and equipment failure can lead to substantial repercussions, both economically and operationally. The integration of HPP solutions ensures that such risks are mitigated, providing a robust framework that supports uninterrupted operation. For example, industrial plugs and sockets can benefit from HPP frameworks to increase their resilience.

Moreover, high-performance solutions contribute significantly to the advancement of industrial technology. By incorporating cutting-edge materials and manufacturing techniques, HPP solutions enhance the overall longevity and resilience of industrial equipment. This not only elevates the performance standards but also aligns with sustainable practices by extending the lifecycle of components, ultimately resulting in cost-effectiveness and resource conservation. These benefits can be amplified by utilizing quality Plastic Systems cables that meet HPP requirements.

As industries continue to evolve, the role of HPP solutions is likely to expand, driving innovation and fostering the development of more sophisticated and adaptive systems. Their intrinsic value lies in their capacity to transform theoretical potential into tangible, high-efficiency outcomes, making them an integral component in the pursuit of industrial excellence.

Industrial Plugs and Sockets

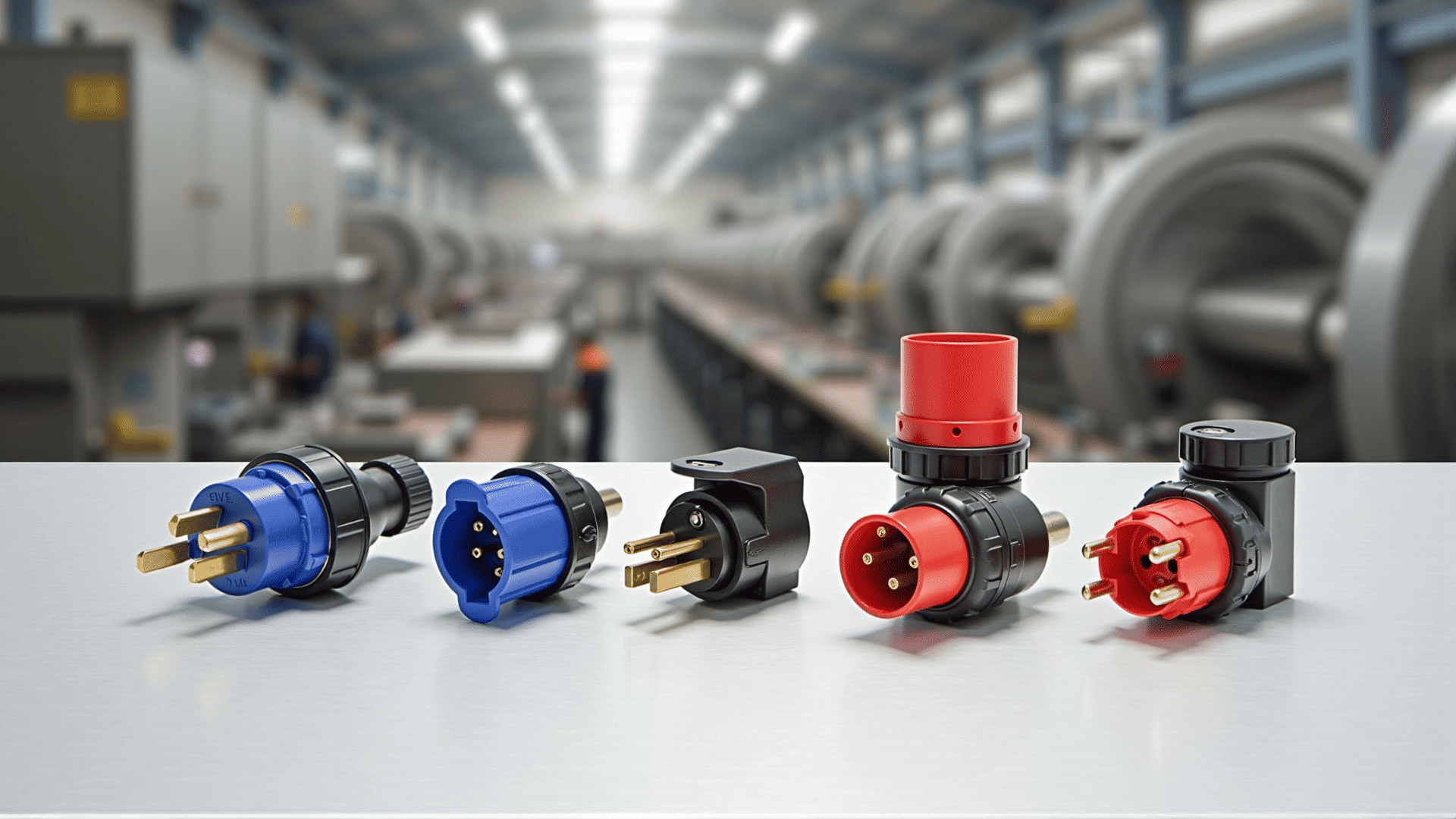

In the realm of industrial applications, the choice of industrial plugs and sockets is paramount to ensure operational efficiency and safety. These components are pivotal as they facilitate the seamless transmission of electrical energy between different machinery and infrastructure setups. The intricate engineering behind industrial plugs and sockets allows them to endure not only high voltages but also adverse environmental conditions, including exposure to dust, moisture, and temperature fluctuations. Such resilience is attributable to the robust materials employed in their construction, typically involving high-grade thermoplastics and metals that resist corrosion and wear.

Moreover, these devices are often equipped with innovative locking mechanisms and protective features to mitigate the risk of accidental disconnections and electrical hazards. By adhering to stringent industry standards and certifications, manufacturers ensure that these plugs and sockets deliver optimal performance. A key aspect of their design is versatility, enabling compatibility with a wide array of devices and configurations, which significantly enhances their utility within diverse industrial sectors.

Efficiency in the context of industrial plugs and sockets is not merely about energy conservation but also encompasses the reduction of downtime, the minimization of maintenance requirements, and the promotion of longevity through durable design. By strategically selecting appropriate types and configurations, industries can achieve not only operational excellence but also a sustainable energy footprint, which is increasingly critical in today’s environmentally conscious landscape. Thus, a profound understanding of the specifications and capabilities of these industrial connectors can empower organizations to harness their full potential, ensuring that they are not merely components of a system but integral to fostering an innovative and efficient industrial environment.

Integration of Performance and Efficiency

In the realm of modern electrical solutions, the synergy between performance and efficiency has become a linchpin for innovation, driving the development of groundbreaking technologies. The integration of these two critical elements begins with a comprehensive design philosophy that emphasizes holistic engineering practices. At the core, this involves an intricate understanding of power dynamics, thermal management, and material science. By harnessing advanced semiconductor materials and leveraging cutting-edge circuit architectures, engineers optimize the intrinsic performance metrics without forsaking energy efficiency.

One of the pivotal advancements fueling this integration is the proliferation of smart power management systems. These systems dynamically modulate power consumption in response to real-time data inputs, ensuring that electrical solutions operate at peak performance while minimizing energy wastage. Furthermore, the use of algorithms in power electronics facilitates rapid adjustments to voltage and current parameters, thereby refining efficiency at a micro level.

In parallel, the advent of sustainable energy sources and the progressive electrification of industries have cast a spotlight on the need for high-efficiency solutions. Through the deployment of renewable energy systems, such as solar and wind, the quest for elevated performance intersects with the drive for smaller carbon footprints. The seamless interaction between distributed generation networks and high-efficiency base-load technologies, including solutions like Plastic Systems cables and industrial plugs and sockets, exemplifies a sophisticated integration of performance and efficiency, propelling the sector towards an energy-efficient future.

The integration is further bolstered by the emergence of the Internet of Things (IoT) and artificial intelligence (AI) in electrical systems. These technologies enable predictive maintenance and adaptive control, which enhance system longevity and performance metrics. Real-time analytics facilitate deep insights into system operations, enabling optimizations that accrue incrementally but significantly over time.

Thus, the integration of performance and efficiency in modern electrical solutions emerges as a testament to human ingenuity and technological advancement. It reflects an ongoing dialogue between innovation and environmental stewardship, with engineers consistently pushing the boundaries of what is feasible in power management, leading to solutions that are not just efficient but also resilient and adaptable to changing energy paradigms.

Future Prospects of Electrical Charging Solutions

As technology incessantly marches forward, the realm of electrical charging solutions is poised for monumental transformation. The shifting sands of consumer behavior, coupled with regulatory nudges towards sustainability, are galvanizing unprecedented innovation in this space. A pivotal trend is the advent of ultra-fast charging technologies, designed to mitigate the perennial inconvenience of prolonged downtime. Advanced solid-state batteries, with their promise of increased efficiency and reduced recharging durations, are set to redefine the performance parameters for electric vehicles and portable electronics alike.

Moreover, the symbiosis of the Internet of Things (IoT) with electrical charging is a burgeoning concept. Smart charging stations, capable of dynamically adapting to real-time energy demands and optimizing electricity consumption through data-driven insights, are on the precipice of becoming ubiquitous. This harmonization not only extends the functionality of electronic devices but also initiates an era where charging processes are seamlessly integrated into the fabric of smart city ecosystems.

In parallel, wireless charging is gaining traction, transcending its erstwhile niche status. Plastic Systems cables that facilitate seamless energy transfer through advanced materials play a significant role in these developments. The allure of eradicating cables and offering unobtrusive energy transfer has spurred significant R&D investment. Enhanced resonance-based and electromagnetic induction systems are being fine-tuned to increase both efficiency and range, with ambitious visions of over-the-air power transmission systems on the horizon.

Furthermore, the integration of sustainable energy sources into charging infrastructures is receiving undivided attention. As the global consciousness orbits around ecological preservation, photovoltaic-powered charging solutions and other renewable interfaces are becoming vital components of modern infrastructure strategy. Not only do they cater to the exigencies of environmental stewardship, but they also offer a buffer against the volatility of conventional energy markets.

The evolution of electrical charging solutions is inexorably linked to advancements in material sciences and electronic engineering. Breakthroughs in nanotechnology and conductive materials, such as industrial plugs and sockets, are instrumental in overcoming existing limitations, enabling the creation of lightweight, flexible chargers that promise heavy-duty performance and endurance.

In essence, the future of electrical charging solutions is not merely about incremental improvements but signifies a profound paradigm shift. As technological prowess converges with environmental imperatives, the pursuit of charging innovation continues to energize the industry landscape, promising a cleaner, more efficient, and interconnected world.