Introduction to Industrial Plugs and Sockets

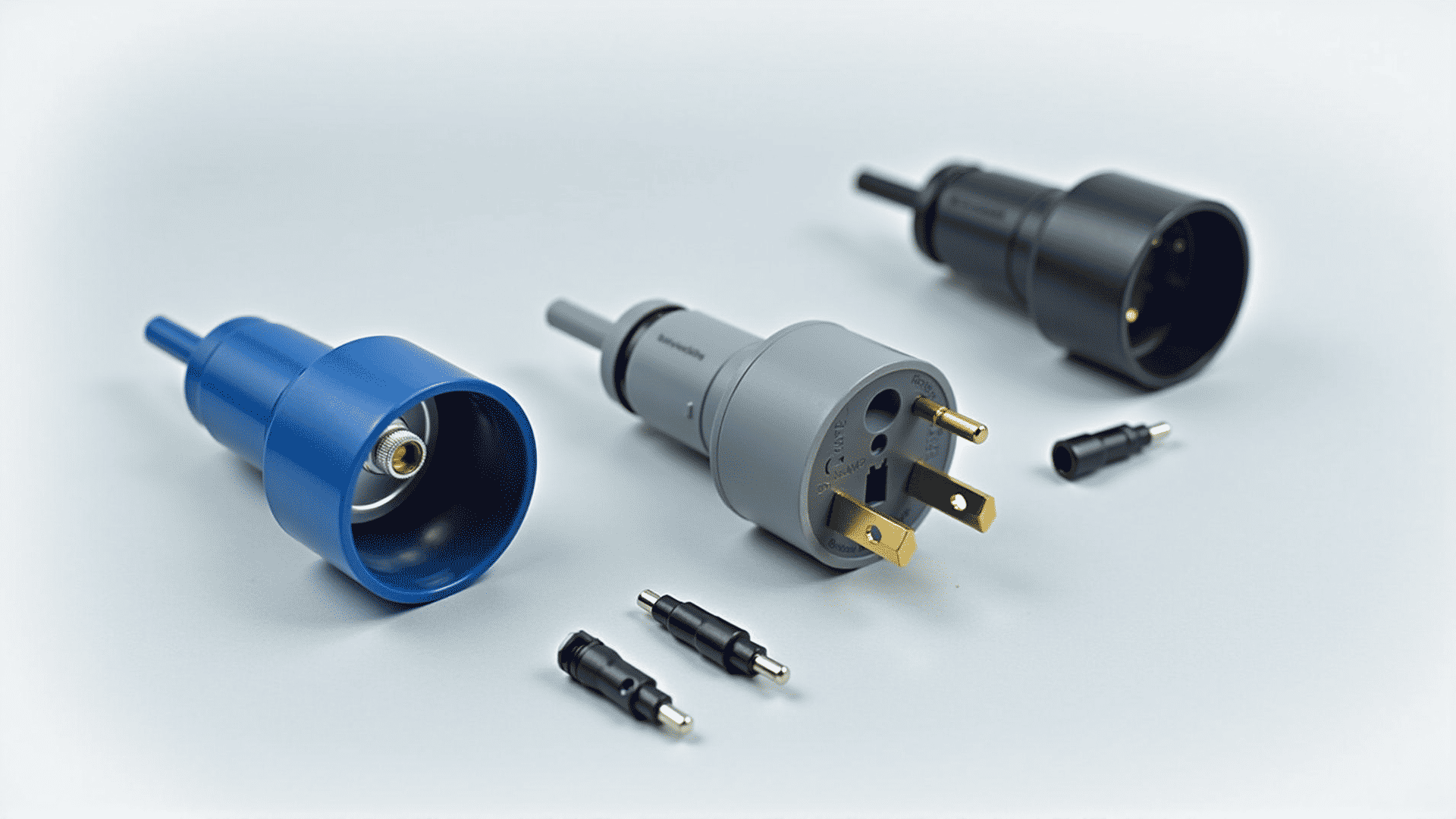

Mennekes is at the forefront of developing industrial plugs and sockets, offering solutions that are not merely utilitarian but pivotal to the seamless operation of industrial infrastructures. These connectors are engineered to endure the rigors of industrial environments, featuring robust materials and precise manufacturing that ensure optimal performance regardless of conditions. Notable for their durability and versatility, Mennekes products are suitable for a range of applications from heavy machinery to sophisticated electrical equipment, playing a central role in maintaining electrical safety and efficiency within industrial settings.

Key to their design is the intricate locking systems that prevent accidental disconnections, coupled with ingress protection ratings that guarantee resilience against dust, water, and other potential contaminants. With an emphasis on reducing downtime and enhancing operational continuity, these connectors are indispensable in sectors where reliability is paramount, such as manufacturing, construction, and shipping.

Furthermore, their ergonomic design facilitates ease of use, which becomes crucial during quick set-ups and maintenance checks. Whether in the implementation of charging solutions for electric vehicles or providing power in remote assembly lines, Mennekes industrial plugs and sockets represent a confluence of pragmatic engineering and innovative foresight, pivotal in advancing industrial efficiencies.

For specialized applications, Mennekes also provides essential accessories, such as Plastic Systems cables, tailored to seamlessly integrate with their industrial connectors, ensuring maximum robustness and operational efficiency.

Key Features of Mennekes Products

Mennekes products exemplify a symbiotic blend of exceptional quality and cutting-edge engineering, making them indispensable in industrial applications. At the core of their design philosophy lies an unwavering commitment to durability, ensuring that each plug and socket can withstand even the harshest environments. Constructed from high-quality materials, these products promise long-lasting performance, safeguarding your electrical connections against wear and tear.

Reliability is another cornerstone that elevates Mennekes above its contemporaries. Their meticulous manufacturing processes guarantee that every product delivers unparalleled dependability, minimizing downtime and enhancing operational efficiency across industries. With a keen eye on evolving industrial needs, Mennekes consistently pioneers innovative solutions that enhance utility without sacrificing robustness.

Furthermore, the use of advanced materials ensures that each component not only meets but often exceeds safety standards, fortifying them against potential hazards. These elements are intricately designed to resist deformation and damage, providing peace of mind by maintaining operational integrity.

For those looking to delve deeper into the components that fortify these products, Mennekes offers a range of auxiliary systems. Discover more about these integral solutions at their Plastic Systems cables page. In conclusion, Mennekes crafts products that do more than connect — they empower industries to achieve new heights of productivity and safety. Explore their charging solutions for comprehensive insights.

Applications in Various Industries

Mennekes plugs and sockets demonstrate a remarkable versatility, becoming indispensable components across various industrial landscapes. Within the automotive sector, they are integral for charging electric vehicles, facilitating efficient energy transfer and ensuring safety in rugged environments. In the food processing industry, these connectors maintain stringent hygiene standards, supporting equipment that requires frequent cleaning and maintenance without compromising electrical integrity.

The construction sector also finds these devices invaluable due to their robust design, which withstands harsh weather conditions and physical impacts while delivering reliable power to machinery on bustling sites. In marine activities, Mennekes connectors are engineered to resist corrosion from saltwater exposure, ensuring seamless operation of shipboard systems.

Moreover, the entertainment industry leverages these connectors for their exceptional durability and ease of use, powering dynamic lighting setups and sound equipment at vast events. This broad spectrum of applications underscores the adaptability of Mennekes solutions, highlighting their role in enhancing operational efficiency and safety across an array of industrial pursuits.

Mennekes’ Charging Solutions

In a world increasingly driven by electrification and the burgeoning demand for reliable energy sources, Mennekes stands at the vanguard of transformative charging solutions. With a steadfast commitment to innovation, Mennekes transcends conventional paradigms by offering an eclectic array of products that cater adeptly to the nuanced requirements of contemporary electrical consumption. Their portfolio is not merely a collection of charging apparatus but a meticulously curated anthology of technological marvels designed to synergize seamlessly with modern infrastructural demands.

Central to Mennekes’ ethos is the symbiotic blend of functionality and forward-thinking design. Their solutions extend beyond the utilitarian confines of traditional charging mechanisms, embodying a philosophy where user-centric design meets sustainable innovation. Enhanced with cutting-edge technology, Mennekes’ Plastic Systems cables are renowned for their uncompromising reliability, scalability, and efficiency, making them a quintessential choice for businesses and consumers alike who seek to embrace the electric revolution.

Furthermore, Mennekes places a profound emphasis on adaptability and future-readiness, ensuring that their solutions can effortlessly evolve alongside the rapidly changing landscapes of electrical needs. By investing in robust research and development, Mennekes not only anticipates future trends but shapes them, ensuring that their customers are always a step ahead in the quest for energy autonomy.

In essence, Mennekes provides not just products but a visionary blueprint for the future of energy, encapsulating the very spirit of innovation and progression. For those keen on exploring more about this electro-innovative powerhouse, further insights can be garnered through their extensive repertoire of resources.

Conclusion and Future Prospects

As we traverse the corridors of industrial evolution, the contributions of Mennekes products emerge as pivotal igniters of efficiency and precision. These innovations have transcended mere functionality, acting as linchpins in optimizing workflow processes and minimizing operational redundancies across various sectors. The profound impact of Mennekes' sophisticated electrical components is an eloquent testament to their prowess in engineering durables that withstand the mercurial demands of modern industries.

Looking toward the horizon of technological progress, one can envisage a vibrant tapestry of advancements propelling electrical component technology to previously unimagined zeniths. The synergy between digitalization and electrification heralds a new epoch characterized by smart systems and integrative solutions. As the industry leans into the fulcrum of the Internet of Things (IoT) and Artificial Intelligence (AI), we anticipate Mennekes spearheading a renaissance in connectivity and adaptive responsiveness.

Moreover, the commitment to sustainability and energy efficiency is likely to catalyze innovations in materials science, spawning eco-friendly components that marry functionality with environmental conscientiousness. As these trends crystalize, the electrical domain will witness transformative developments that redefine the concepts of performance and reliability. Mennekes, with its illustrious heritage of quality and ingenuity, is poised to usher in a future where electrical components, such as their Plastic Systems cables, are not just supportive mechanisms but rather dynamic participants in the overarching narrative of industrial efficiency and advancement.